New progress in the manufacturing and application of large-scale mechanical rollers

Recently, a series of new progress has been made in the field of large-scale mechanical roller manufacturing, which not only improves production efficiency, but also expands the application field, and also puts forward higher requirements for safe production.

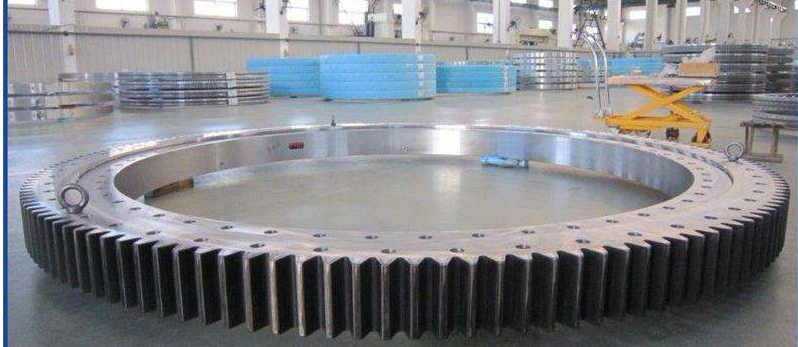

In terms of manufacturing, the application of new materials makes the rollers have higher strength and wear resistance, and increases the service life of the product. At the same time, advanced manufacturing processes also reduce energy consumption and emissions in the production process, reflecting the concept of green environmental protection. In terms of application fields, large-scale mechanical rollers are not only widely used in traditional textile, food, medicine and other industries, but also gradually expand to emerging fields such as new energy and environmental protection. Its efficient and stable performance provides strong support for the development of these industries.

Safe production has always been the top priority of the roller manufacturing industry. Recently, the industry has strengthened safety production training and improved employees’ safety awareness and operating skills. At the same time, by introducing advanced safety monitoring equipment and technical means, the safety risks in the production process have been effectively reduced.

In addition, exchanges and cooperation within the industry are becoming more and more frequent. By holding seminars, exhibitions and other activities, enterprises and research institutions are able to share the latest technological achievements and market trends, which has promoted the rapid development of the entire industry.

Looking into the future, the large-scale mechanical roller manufacturing industry will continue to adhere to the development concept of innovation, greenness and safety, continuously improve product quality and application level, and make greater contributions to promoting the transformation and upgrading of my country’s manufacturing industry.